Description

▪ MK NDT Applications

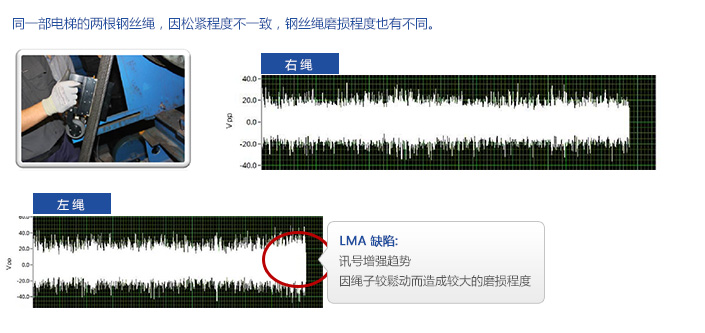

A lift system generally requires several wire ropes for lifting. Different tightness of wire ropes can be resulted in greater abrasion for the loose wire rope or unfavorable compression between wire rope strands for the tightest rope. This will shorten the service life of the loose / tightest wire rope. MKNDT can help you to discover this kind of imperceptible faults at earlier stage.

Objectively reveal the deterioration condition of the rope

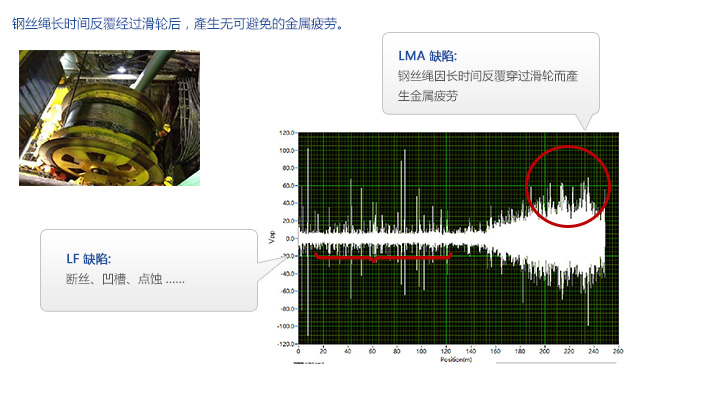

In reality applications, the service life of wire rope depends on various complication factors, for example: • passing through small D/d ratio sheave or pulley for a long period of time and result in metal fatigue; • Unfavorable contact between steel wire rope and pulley/sheave and/or drum; • Present of design flaws of lifting system; • Lack of suitable lubrication and maintenance; and • High humidity and/or present of corrosive gases in the operating environment. These adverse factors would shorten the service life of wire rope. MKNDT can objectively reveal the deterioration condition of the rope and help you to make rope replacement decision.