LINGMAX高強吊帶使用指南

LINGMAX高強吊帶使用指南

雙管吊帶的檢測程式

Test Procedure For Complete Twin-Path® Sling Products

- 在驗證測試中,銷子直徑是26mm(1吋)或更大。

In the proof testing, the pins should be 26 mm (1 inch) diameter or larger. - 驗證測試中,吊帶會被拉至工作負荷的2倍,並保持最少15秒,然後再把吊帶放開。

The slings should be pulled to twice their working load limit. Slings will be held at the proof test limit for a minimum of 15 seconds and then the tension may be released. - 拉力測試機是用來試驗雙管吊帶和承載束芯是否符合或超過ASME E-4標準的要求。

Testing machine is required to test Twin-Path® sling products and load yarn to check if they meets or exceeds the standards as described in ASME E-4. - 吊帶的破斷拉力測試應該按照以上的規定進行和紀錄。所有銷子的直徑必須等於公稱吊帶闊度的一半或大於此直徑。

The break testing of the sling should be conducted and recorded according to the aforementioned rules. All the diameter of pin should equal to the half of nominal sling width or even larger. - 每條新的或者修補好的吊帶必須通過驗證測試。

Proof testing is mandatory for each newly manufactured and repaired Twin-Path® sling. - 當吊帶通過驗證測后,外接警告繩長度會在裝運前修整。

After the sling is proof tested, the tell-tails should then be trimmed to length prior to shipment. - 修補好的吊帶或配件必須通驗證測試后才能重新使用。

Repaired slings or fittings should be proof tested before they are returned to service. - 標準技術可供用家、企業和政府作參考用,以便客戶確保正確使用、維護和檢查雙管吊帶產品。

These recommended standard specifications are the guide to users, industry and govern

雙管吊帶檢查

雙管吊帶檢查

Inspections of Twin-Path® Products

- 外接警告繩應附在吊帶上,如果不見了,吊帶就不能使用;如果吊帶受到化學腐蝕,吊帶也不能使用,要送回生產商評估和維修。

Tell-Tails should be attached to the each sling. If tell-tails are invisible, the sling should be removed from service; if the sling shows any chemical degradation, the sling should be also removed from service and sent to manufacturer for evaluation and repair. - 檢查吊帶外套是否有任何割壞和撕裂是重要的,外層保護套受破壞可表示內層纖維芯也受破壞。因此吊帶受損壞必須暫停使用,送回生 產商評估和維修。

This is important for personnel to inspect any cutting or tearing on the outer cover of sling. Damage on the cover may indicate core yarn would be damaged as well. Hence slings with cuts should be removed from service, sent to the manufacturer for evaluation and repair. - 檢查吊帶是否受熱力損壞。人造纖維的防焰吊帶不可在溫度超過攝氏149度/華氏300度使用;K-Spec®和聚酯吊帶不可在溫度超過攝氏 82度/華氏180度使用。低溫至攝氏-40度/華氏-40度不會影響吊帶強度。其它溫度對吊帶的影響可向生產商查詢。

Slings should be inspected by any heat damaged. Aramid Sparkeater slings should not be exposed to temperatures over 149℃/ 300°F; K-Spec® and polyester core slings should not be exposed to temperatures above 82℃/180°F. Low temperature to minus 40℃/ minus 40°F do not affect the strength of slings. The effect of other temperatures on slings can be referred to the manufacturer. - 連線吊帶的鋁配件,不可在煙霧、水蒸氣、噴霧、酸霧或堿霧的環境中使用。

Slings using with aluminum fittings should not be used where fumes, vapors, sprays, or mists of alkalis or acids are present. - 雙管吊帶和其它配件必須定期檢查,初次檢查應該由合資格的檢查人員進行和記錄。此外,每次使用前吊帶必須進行檢查。

Twin-Path® slings and any fittings attached should be inspected regularly. The initial inspection should be done and recorded by a competent person. Besides, the slings should be visually inspected before each use. - 檢查報告應該要記錄好和儲存在工廠的安全部門或使用現場。合資格人員可根據使用頻率、環境狀況和過往使用經驗, 來進行更頻密的檢查。

Inspection reports should be recorded and kept on files in the safety department of the plant or site where used. Inspections may be done more frequently based on the frequency of use, severity of conditions, experience of past service life. - 吊帶必須進行整條全面檢查有沒有任何磨損、割破、高熱損壞、配件變形或損壞、難讀標籤。如果檢查員對吊帶有任何懷疑,吊帶應該 要停止使用。光纖檢測系統可確定承載芯束的完整性,如果有損壞情況,吊帶必須停止使用和送回生產商評估。

Slings should be examined throughout their length for any abrasion, cuts, heat damage, fitting distortion or damage, illegible tag, and if any doubts are held by the inspector, the sling should be removed from service. Core integrity is determined by Fiber optic light transfer. If deterioration is found, the sling must be removed from service and returned to the manufacturer for evaluation. - 不能修補的吊帶必須歸還和銷燬,不可再次使用。

Slings removed from service that are not repairable should be rendered and destroyed completely unfit for future use. - 外層保護套有磨損、高熱損壞、割破錶示承載束芯的強度已經減少和吊帶必須暫時使用,待生產商評估。在損壞的位置,外層保護套應 該打開,用目視檢查承載束芯數量。

Abrasion, heat damage or cuts on the cover may indicate a loss of strength to the load core and these slings should not be used until evaluated by the manufacturer. At the area of damage, cover should be opened and the number of core yarns should be visually inspected and counted.

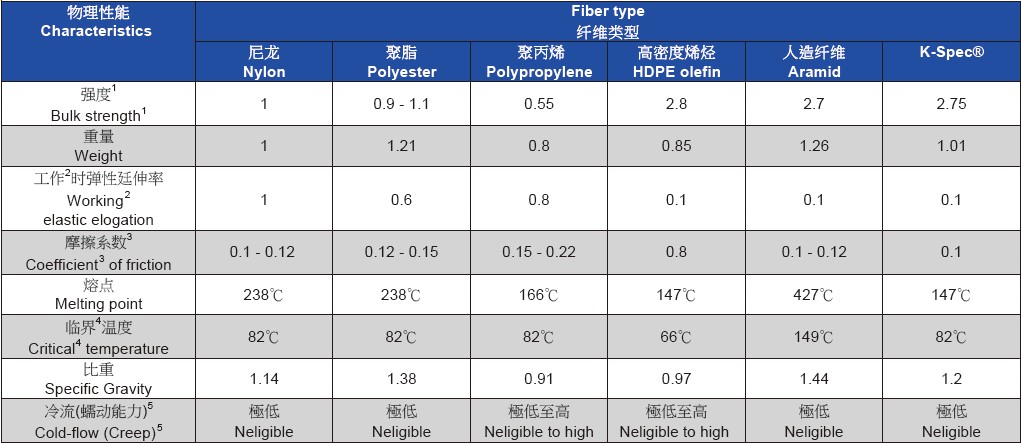

各種合成纖維物理效能

各種合成纖維物理效能

Fibers Characteristics

- 以尼龍作為基數 =1

- 1:強度是每平方周長的力量。

2:工作是繩索實際使用時循環載荷。

3:摩擦係數是基於滑動阻力。

4:臨界溫度是在某一點時,降解是隻因為溫度變化引起。

5:冷流(蠕動能力)是根據平穏靜態負載情況下,因分子滑動而引起纖維變形(廷長)。

如果載荷有較少的變化,擁有本身特徵的纖維會顯示極少的蠕動。聚丙烯、聚乙烯和高密度烯烴纖維會做成繩子。 - 1:Bulk strength is defined as strength per circumference squared. 2:Working is defined as rope actually in use under a cycling load. 3:Co-efficient of friction is based on reluctance to slip or slide. 4:Critical temperature is defined as the point at which degradation is caused by temperature alone. 5:Cold-Flow (Creep) is defined as Fiber deformation (elongation) due to molecular slippage under a constant steady static loading situation. Fibers that have these inherent characteristics will display extremely low or negligible creep if minor fluctuation occurs in the rate and/or frequency of load levels. In rope form, this would apply to polypropylene, polyethylene and HDPE olefin Fibers.

環境因素

環境因素

Environmental Considerations

- 合成纖維吊帶在不使用時,應存放于乾淨和乾燥的地方,而不是高溫和不通風的地方。

When not in use, synthetic slings should be stored in a clean and dry place rather than high temperature and unventilated places. - 在充滿化學制品環境下會影響合成纖維吊帶的強度。不同的化學制品會與Covermax® 尼龍、聚酯、人造纖維和烯烴產生不同的化學 反應。

Chemically active environments can affect the strength of synthetic slings. Different chemicals will react with different exposure to Covermax® bulked nylon, polyester, aramids and olefins. - 人造纖維對大多數的酮、酒精、乾性清潔溶劑和其它有機溶劑具有抵抗力。它對抗酸效能力比尼龍好,但比聚脂弱。人造纖維在室溫時 有好的抗堿能力,但在高溫時強堿使人造纖維抵抗能力較變差。

Aramids are resistant to most ketones, alcohols, dry cleaning solvents and other organic solvents. Their acid resistance are superior to that of nylon but are not as good as that of polyester. Aramids show good resistance to alkalis at room temperature, but are degraded by strong alkalis at high temperatures. - 人造纖維在高溫下和含氟的彈性體、樹脂和製冷劑是相容的;但在高濃度的氟化物中有抵抗力,而這些混合物一般來自冶金和採石業。

Aramids are compatible with fluoride-containing elastomers, resins, and refrigerants at high temperatures, and are resistant to fluorine compounds in concentrations usually encountered in stack gases from metallurgical and rock-processing operations. - 在室溫下,人造纖維對硫氧化物的抵抗力,在酸性露點以上比聚脂好。在露點以下,濃縮的硫酸會集中在纖維,使纖維的強度逐漸 減少。

The resistance of aramids to sulphur oxides at temperatures above the acid dew point is superior to that of polyester. Below the dew point, concentrated sulphuric acid may condense on the Fiber and cause a progressive loss in strength. - 在中等至強酸性或鹼的環境下,必須對人造纖維作出評估,以確保纖維在使用前效能良好。

In moderate to strong acid or alkali environments, evaluation of aramids should be made to ensure that the yarn will perform acceptably before use. - 以下大部分的混合物不會對聚脂和尼龍有太大的影響: 酒精、乾性清潔溶劑、卥化碳氫化合物、酮、肥皂、合成清潔劑和水(包括海水)

Polyester and nylon are not significantly affected by most compounds of the following classes: Alcohols, dry cleaning solvents, halogenated hydrocarbons, ketones, soaps and synthetic detergents, and water (including sea water) - 聚脂對以下液體有良好的抵抗能力:

─ 在沸騰點中大部分的弱酸液體、在室溫下大部分的強酸液體;但在室溫下濃度為95%的硫酸會使聚脂碎裂;

─ 在室溫下的強堿液體,但在沸騰時聚脂會降解;

─ 氧化劑和紡織業用的一般漂白處理不會把聚脂降解。

Polyester also shows good to excellent resistance to:

─ Aqueous solutions of most weak acids at the boil, and to most strong acids at room temperature, but is disintegrated by concentrated (95%) sulphuric acid at room temperature;

─ Aqueous solutions of strong alkalis at room temperature, but is degraded at the boil;

─ Oxidizing agents, and is not degraded by bleaching treatments ordinarily used for textiles. - 尼龍不會明顯受大部分的乙醛、堿、乙醚或碳氫化合物的影響,但會被經稀釋的酸所退化(在室溫下濃度為10%的鹽酸和硫酸,10個 小時內會使尼龍受到明顯的強度降低。)

Nylon is not significantly affected by most aldehydes, alkalis, ethers, or hydrocarbons, but is deteriorated by dilute acids (e.g. hydrochloric acid and sulphuric acid in 10% concentrations at room temperature cause a noticeable loss in breaking strength in 10 hours). - 尼龍的溶劑包括:

濃縮蟻酸、室溫下的酚類化合物和室溫下的甲醇中的氯化鈣。

Solvents for nylon includes:

Concentrated formic acid, phenolic compounds at room temperature, calcium chloride in methanol at room temperature. - 在沸騰時苯甲醇中的氯化鋅熱溶劑

Hot solutions of zinc chloride in methanol Benzyl alcohol at the boil. - 人造纖維對大部分的弱酸、弱堿、酮、酒精、碳氫化合物、油、乾性清潔溶劑具有抵抗力。 特別高溫高濃度時,強酸;強堿和次氯酸鈉漂白劑會破壞人造纖維。

Aramids are resistant to most weak acids and alkalis, ketones, alcohols, hydrocarbons, oils and dry cleaning solvents. Strong acids and bases and sodium hypo-chlorite bleach attack aramids, particularly at high temperatures of high concentrations. - K-Spec®纖維芯束強度保持不變是基於在長達6個月,攝氏65度/華氏150度中試驗結果出來。 K-Spec®暴露在10%洗潔劑溶液、腐蝕劑、致霉物、陽光和甲苯,可保持100%強度; 暴露在醋酸、汽油、1m鹽酸、液壓油、煤油和海水,可保持99%強度; 暴露在25%氨水、10%磷酸鹽溶劑和40%磷酸時,可保持98%強度;暴露在5m氫氧化鈉時,可保持97%強度; 暴露在硅酸鹽水泥和硫酸,可保持95%強度;暴露在次氯鈉酸和硝酸,可保持88%強度。

- K-Spec® core yarn strength retention is based on test results of components at 65℃/150°F (or less) for 6 months. K-Spec® has a 100% strength retention when exposed to age, 10% detergent solution, rot and mildew, sunlight and toluene; 99% strength retention when exposed to acetic acid, gasoline, hydrochloric acid 1m, hydraulic fluid, kerosene and sea water; 98% retention when exposed to 25% ammonium hydroxide, 10% hypophosphite solution, and 40% phosphoric acid; 97% retention when exposed to 5m sodium hydroxide; 95% retention when exposed to Portland cement and sulfuric acid; and 88% retention when exposed to Clorox®, and nitric acid.

使用前指引

使用前指引

Guidelines Before Using

- 貨物的重量應該限制在吊帶的工作負荷之內。

The weight of the load should be limited within the WLL of the sling. - 當選擇合適的吊帶時,貨物的型式、吊裝方式和環境因素都要考慮。

The type of load, hitch and environment factors should be considered when selecting a suitable sling. - 吊帶在裝載時不能超過其工作負荷。請注意吊裝角度、銷子的直徑和邊緣也會影響吊帶的工作負荷。

Slings should not be loaded in excess of the WLL. Be aware that angle of lift, diameter of pins and edges may affect the WLL of the lifting sling. - 以工作負荷來計算,結套式吊法在眾多吊法中效用最少。結套式吊帶不應使用錘子或其它工具硬把吊帶緊緊的抱住貨物。 爲了保持貨物平衡,建議使用兩個結套式吊法。只用一個結套栓在貨物中間,會使貨物重心不平衡,導致意外發生。

Choker hitches are the least effective way to use a sling based on the WLL. Slings used in a choker should not be forced to tighten around the load by pounding with hammers or other objects. To maintain balance of the load, two chokers are suggested to be used. Using one choker in the center of the load may create an unbalanced situation which could lead to an accident. - 籃吊方式應保持貨物平衡,以防止貨物滑動和意外發生。

Slings used in a basket hitch should keep balance on the load for preventing slippage and accidents. - 吊帶應和其吊帶配件互相配合;貨物重量應比其吊帶和配件的工作負荷輕;使用正確的配件形狀和尺寸可以確保吊帶緊密連線。

Slings should be compatible with the accessories used. Also, the weight of load should be lower than the WLL of slings and accessories. Proper shape and size of accessories should be used to assure the sling would seat properly. - 吊索應免受切割和邊緣所傷;不要讓吊帶與突出物和粗糙表面產生磨擦。如果磨擦是無可避免,建議把CornerMax™專用保護角放在 吊帶和貨物之間。卸扣銷子範圍會割傷吊帶,除非採取了保護措施,否則不要把吊帶直接掛在銷子上。

Slings should be protected from cutting and edges. All protrusions and abrasive surfaces should not chafe with the sling. If friction is unavoidable, CornerMaxTM Pad is recommended to be placed between the sling and the load. The pin area of a shackle can cause synthetic slings to cut, so placing synthetic slings on the pin should be avoided unless it is protected. - 不要把吊帶拖到地上,或跟其它東西表面拖行,這樣會損害吊帶。

Slings should not be dragged on the floor or drawn across other surfaces which may damage the sling. - 不可爲了縮短吊帶而把吊帶扭曲或者打結。

Never twist or tie the sling in knots to shorten. - 當貨物懸掛時,不可以拉承載中的吊帶。

Never pull the sling from under loads resting on the sling. - 不要把物件放在吊帶上,或者駕車輾過吊帶。

Never drop objects on sling or run over them with vehicles. - 不要使用已損壞的吊帶。

Never use the damaged slings. - 確保每種吊裝方式可以控制貨物的平衡。

Make sure each sling hitches can control the balance of the load. - 在進行吊裝時,任何人都不能位於吊帶和貨物之間、吊帶和任何吊重配件比方說鉤子。

When lifting, personnel should be kept away between the sling and the load, and between the sling and any lifting accessories like hooks. - 任何人不能站在懸吊的貨物下。

Personnel should stand clear of suspended loads. - 任何人不能騎在吊帶或懸吊的貨物上。

Personnel should not ride on the sling or suspended loads. - 不要抓住或撞擊貨物。

Never snatch or shock loading. - 不要把吊帶的腿扭曲和打結。

Never twist and kink the legs of the sling. - 貨物應該掛在吊鉤鉤座的中部,而不是鉤尖位置。

Load applied to the hook should be centered in the bowl of the hooks rather than the mouth of hooks. - 起吊時不管有沒有貨物,要小心留意吊帶折斷的可能。

Personnel should be alert for possible snagging during lifting with or without the load. - 吊帶應該抱住或從側面支援貨物,以重心上方的位置來提升貨物,這樣貨物在起吊時不會傾斜。

The slings should hold or support the load from the sides above the center of gravity, so that the load will not tilt when lifting the load. - 合適的吊帶長度可確保吊帶和貨物之間的掛角,不會減低吊帶的工作負荷。

Proper length of slings can ensure that the angle of the slings to the load does not reduce the WLL of the sling for a given angle. - 只使用清楚標籤的吊帶;如果標記不清晰或丟失,吊帶不得使用。

Only use legibly marked or labeled slings. If the tag is not legible, or missing, the sling must not be used. - 把標籤遠離貨物、鉤和結套式吊法的套角位置。

Keep labels or tags away from the load, the hook and the angle of choke. - 在每次使用吊帶前都要進行檢查。

Inspection of synthetic slings must be done before each use.