Description

Twin-Path® Extra Covermax® Slings

Twin-Path® Slings are the world’s first truly ergonomic sling, which are made in sizes up to 225 tons vertical rated capacity. Outer layer is made of a bulked nylon for strengthening abrasion resistance. Besides, these slings have other unqiue features:

• 4 Main Safety Indicators – Double layer cover, Fiber optic inspection, Overload tell-tails and check fast inspection system.

• K-Spec® – the longest lasting load bearing core yarn

• 10% of the weight of a steel sling

• Less than 1% stretch at rated capacity, when comparing with braided polyester round slings which can stretch up to 9%.

• Can be repairable for safety and cost-saving

If ergonomics, productivity and safety are important, then Twin-Path® slings are the only choice. That is because this is the lightest and strongest sling on the market today.

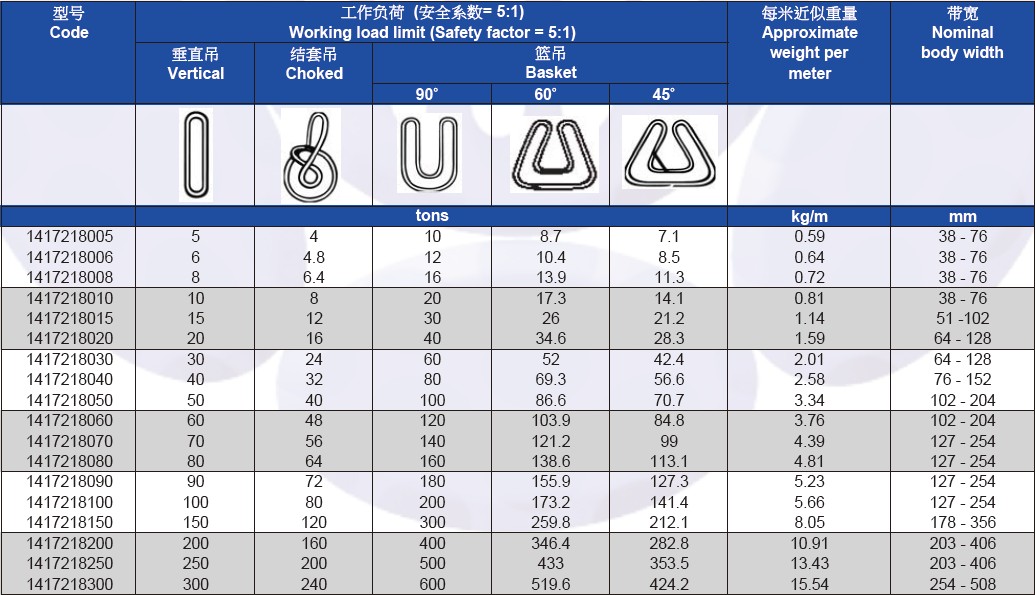

Twin-Path® Extra Covermax® Slings Specifications

Twin-Path® Slings with safety factors 6:1 and 7:1 can also be fabricated upon request. For Twin-Path® Slings over 300 MTS, please contact Mak Kee for further details.

Conforms to ANSI/ASME B30.9 chapter 6, NAVFAC P-307 section 14.6.4.3, and the Cordage Institute Roundsling Standard.

4 Safety Inspection Designs

Accident is unpredictable and unavoidable. If we can control or even diminish the possibility of accident happens, this is absolutely beneficial to each employers and employees. Hence Slingmax innovates a series of safety inspection designs on Twin- Path® slings which is different from the wire rope and webbing slings. These designs can lower the probability of accident happens as well as the lost of additional money and time.

Double Layer Design

Fiber Optic Inspection (For All Twin-Path® Slings)

Twin-Path® slings have the Fiber Optic inspection system. The condition of the internal core yarn can be inspected just by checking the continuity of the Fiber optic cable. If crushing or cutting, heat or chemical damage, has occurred then the damage to the Fiber optic cable will destroy its ability to transmit light from one end to the other giving the inspector a reason to remove the sling from service and send it in for repair evaluation.

The Fiber optic cable will conduct light using natural, overhead or flash light sources. Inspector simply covers and removes his finger from one end and watches the other end for blinking which indicates that the sling is OK to use for another lift.

The Check-Fast® System is designed to improve job-site safety. The ✓Fast® Tag and External Warning Indicator (EWI) on a roundsling product provides for a pass/fail inspection of the internal load bearing core yarn. Damage to the core yarn from Fiber on Fiber abrasion, fatigue, and severe overload can be detected. If the sling is mistakenly overloaded beyond rated capacity, the EWI is designed to disappear before the sling fails.

If the sling cover is intact and the Check-Fast® Tag and EWI are visible, the sling may be used for another lift. This safety system is available for polyester or High Performance K-Spec® Fiber Roundslings fabricated by Mak Kee.

Instructions for Check-Fast® Inspection

Read the information on the sling tag to identify the rated capacity for the hitch to be used, the type of cover and core, the manufacturers’ name, and the warnings and instructions on the tag. Be sure the information complies with existing standards.

Then:

1. Inspect the circumference of the roundsling for holes, tears and other damage to the outer cover. If damage is discovered, take the sling out of service and send it back to your dealer for evaluation.

2. Visually inspect the tag area and ensure the sling is equipped with the Check-Fast® Inspection System as evidenced by the ✓Fast® Tag.

3. Visually inspect the tag area for the EWI. If the EWI is missing or not visible, take the sling out of service and send it back to Mak Kee for evaluation. Do not use the sling.